The DIY lithium battery bank; Bob Ebaugh has 330 cycles so far

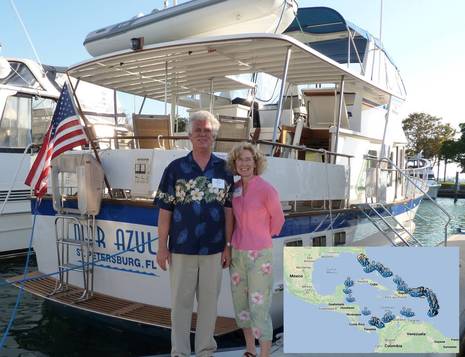

Bob and Elaine Ebaugh did it, leaving Florida in April, 2011, on their DeFever 44 Mar Azul and spending more than two years cruising a big Caribbean loop. Their blog, Mar Azul Adventures, is a good read, but you might miss the fact that during the cruise Bob managed to research, assemble, test and install a 1,200 amp hour do-it-yourself lithium iron phosphate (LiFePO4) battery bank to replace the 12 golf cart batteries they'd worn out. He also wrote a thorough white paper about why he chose DIY lithium and how he put the system together...

Here is Bob's lithium battery blog entry, but you really should download the 14-page PDF mentioned there. Even if you're not ready to build your own LiFePO4 battery bank -- and most of us probably shouldn't at this point -- Bob seems to have done a fine job of analyzing the pros and cons of different battery types, particularly for fairly heavy power users like Mar Azul (at 400-600 Ah per liveaboard day on the hook).

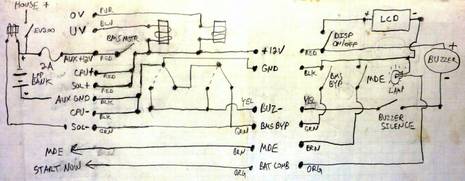

This photo shows the DeFever's "workshop" (forward cabin). Bob's first task was to assemble forty-eight individual 3.2V cells made in China by GB Systems into twelve 100 Amp hour 12V batteries, and here I believe he's bench testing the Elite Power battery management system (BMS) whose components are seen below. His PDF gives specifics about where he sourced the GBS cells and BMS and why, as well as a link collection for further research.

There's a lot to managing lithium batteries properly, and there's a definite safety concern. Their wonderful ability to take a large charge quickly, thereby reducing generator and/or alternator times, also means that they can release their charge very quickly, which means intense heat in the wrong circumstances. There have apparently been boat fires that originated in lithium battery banks, though the facts usually seem hard to come by (possibly because most marine lithium installs so far have been high-end projects).

At any rate, I'd suggest that anyone (including myself) who doesn't thoroughly understand Bob's well-written explanation of how he set up his BMS, diagrammed above, and adjusted his various charging sources for their new LiFePO4 target should not consider a DIY lithium bank. But I'm really glad that guys like Bob are trying such things and sharing their findings. Note also that since coming back ashore, Bob has been doing marine electronics professionally and hopes to write a Panbo entry about a substantial ePlex distributed power system he's working on, which will join his earlier pieces on bridging NMEA to Ethernet, his Chetco engine monitoring system, and testing various sat phone systems. Meanwhile, here's the latest on Mar Azul's lithium batteries:

The lithium bank is still functioning well. But I have not done any cruising for almost a year now, maybe 2 Saturday nights. I really like the operational characteristics, but the cards are still not all on the table.

About the only thing additional I completed {since writing the white paper} is a benchmark test on capacity. My theoretical 1200 Ah bank is really more like a 1050 Ah bank. So in one year of cruising, theoretically I lost about 15% of rated capacity. What I don't have is an actual pre-installation benchmark, though the importer suggested that as shipped, and tested the way I did, they would have shown 95% of the rating; so maybe we only lost 10%. We did have 330 cycles in that timeframe.

Some research indicates capacity loss is also very related to calendar life and storage temperature. The end of August gives me another 12 months so I will run another test and see what we have now, with the bank essentially in storage.

There is so much we don't know. Not only about "life", but exactly how volatile they are if severely overcharged. This winter, I may buy a few 40Ah cells and do some destructive testing.

RC Collins is apparently also testing lithium marine batteries and he, Bob, and several other marine power luminaries sit on a ABYC subcommittee studying LFP (another name for LiFePO4) battery technology under the chairmanship of Bob's current boss/mentor Charlie Johnson. Thanks to them all, and don't we look forward to hearing the results?

Share

Share

So what to we think 2 years later? A bit more detail than I provided Ben in the email he quoted above.

The operational characteristics for live aboard at anchor are nothing short of phenomenal. No more worries about full charging or periodic equalization. Just use what energy you need and put it back when you can. And you always get to put it back at full rate!

M/V Mar Azul is an incredibly power hungry vessel for living at anchor. We destroyed 12 Trojan T105's getting from Florida to Grenada. The boat uses an average of 20-25A at 12V at anchor, mostly running inefficient refrigeration. 3 systems, 2 fridges and one chest freezer. Operationally after returning, the LFP system appears to operate like the day we installed it.

But...I wanted to establish a baseline capacity test. Cycle life is the holy grail to justification of the cost and effort of installing LFP. So shortly after we got back I purchased a battery tool that allowed me to capture the data during charge discharge cycles with the batteries removed from the boat on the bench. See:

http://www.revolectrix.com/pl6_description_tab.htm

This rig allows me to charge or discharge at a 30A constant rate at 12V and record the data. Running a sample of 4 cells of my 48 through capacity testing, I discovered my 100Ah cells were more like 85Ah cells. This was disappointing. Discussion with my battery supplier indicated this test would have likely shown around 95Ah on delivery. So that's 10-15% capacity fade depending on how you want to look at it.

I've also run new Calb and Forzatec cells through the same test when new, and both met rated capacity.

This turn of events led to more reading of research papers, some suggesting that temperature and calendar life are significant contributing factors to cycle loss, perhaps even more so than number of cycles. Mine are in the engine room (bad choice), so on longer legs, they heat up to almost ambient engine room temperature of about 120 degrees F in the tropics. This is well within the manufacturers discharge specification, but not charging. I don't charge underway since my alternators are set to simply maintain 13.2V, but they do trickle charge a bit on occasion.

One topic I glossed over in my original material is addressing the safety of LFP batteries in the marine environment. And to be very clear, I'm not a chemist, or an engineer by education. But I have read at one point or another just about every paper I could find published on the internet.

More recently, I drew up some conclusions and bounced those at a very high level with some PhD types that were willing to answer. I don't have the answers, but feel I better understand the questions.

First, large capacity battery banks are inherently unsafe, no matter the chemistry. It's just like having 950 gallons of diesel, or worse gasoline onboard. What we do is take logical precautions to mitigate that risk. But not eliminate the risk, it's not possible. Until more is known, I suggest:

1) Do everything with LFP suggested for any large battery bank, cut no corners

2) Make absolutely sure there are multiple automatic fail safes to prevent overcharging

3) The fail safe must include cell level voltage and bank level temperature monitoring

That mitigates the risk significantly, and is consistent with what most packaged systems are doing.

What we don't know (or what I haven't been able to figure out yet):

1) Exactly how hot a LFP cell will get if it is overcharged. We know it's the safest kind, chemically it won't add heat on it's own, or what's called a runaway, like the old famous laptop cells, or perhaps the Boeing Dreamliner cells. But if you overcharge them, after the cell is full, all that energy becomes heat. Until it eventually blows the seal and vents the electrolyte.

2) Exactly how volatile, and what the other characteristics of the gas that gets vented. Is it lighter than air? Is it the same between different cell manufacturers based on what they exactly use for an electrolyte? We know this can happen, by overcharging, by a faulty cell shorting out and by any accident that could pierce the case.

We do a pretty good job mitigating risk for overcharging, but in the unlikely event of venting, no one seems to have much data, or data I understand well.

The "LFP Technology" is in it's infancy stage. Maybe will become be the next "lead acid" and last for many years, or be superseded by some new tech, not yet on the market.